Acid-proofing involves applying protective coatings or materials to surfaces to protect them from acid corrosion. This technique is commonly used in industries like chemical processing, pharmaceuticals, metallurgy, and wastewater treatment, where surfaces are exposed to acidic environments.

Key acid-proofing methods include:

- Special Coatings: Acid-resistant paints, resins, or polymer coatings are applied to protect surfaces.

- Acid-Resistant Bricks or Tiles: These materials line surfaces to prevent acid corrosion.

- Acid-Resistant Cement: Specialized cement is used with bricks or tiles to withstand acidic conditions.

These techniques extend the life of equipment and structures by preventing acid-related degradation.

Applications of Acid-Proof Bricks

- Chemical Plants: Used in reactors, chimneys, towers, and storage tanks that process or store acids.

- Pharmaceutical and Food Processing Industries: Used in floor and wall linings where there is regular contact with acidic chemicals during production processes.

- Power Plants: Used in flue gas desulfurization systems, chimneys, and other structures where acidic gases are handled.

- Water Treatment Facilities: Used in wastewater treatment plants, where acidic waste and chemicals are processed and stored.

- Petrochemical Industry: Utilized in tanks, vessels, and pipelines that handle acidic hydrocarbons.

Common Acid-Proofing Materials

- Acid-Resistant Bricks

Acid-proof bricks are specialized ceramic materials designed to resist chemical corrosion. They are commonly used in industries like chemical processing, power plants, and wastewater treatment.

Key Features:

- Chemical Resistance: Effective against acids like sulfuric, nitric, and hydrochloric.

- Durability: Long-lasting even in aggressive environments.

- Low Absorption Rate: Resistant to moisture penetration, reducing chemical attacks.

- Thermal Resistance: Suitable for high-temperature applications.

- Mechanical Strength: Can handle heavy loads while providing chemical protection.

Types of Acid-Proof Bricks:

- Silica Bricks: Resistant to high temperatures and acids (except hydrofluoric acid).

- Fireclay Bricks: Ideal for low to medium acid concentrations.

- Carbon Bricks: Highly resistant to strong acids like sulfuric acid.

- Antacid Bricks: Made from silicates, they resist high concentrations of corrosive chemicals.

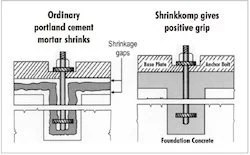

2. Acid-Resistant Cement

- Description: This cement incorporates acid-resistant compounds like silicate.

- Applications: Used alongside acid-resistant bricks for floors, walls, and tanks in chemical plants.

3. Epoxy and Vinyl Ester Resins

- Description: Polymer-based coatings offering durable barriers against acids.

- Applications: Commonly used on tanks, pipes, and equipment in chemical industries.

4. Acid-Proof Tiles

- Description: Made from silica, porcelain, or vitrified ceramic, these tiles resist acids.

- Applications: Used for flooring and surface lining in labs, chemical plants, and food processing facilities.

These materials are chosen based on factors like acid type, concentration, temperature, and structural needs.

Contact Us:

Sai Balaaji Refractories Private Limited

Plot No.27 South Phase, Ambattur Industrial Estate, Ambattur, Chennai – 600058

Phone: 044 2623 2030 / 044 4208 3688 / 044 4206 0520

Email – balaajiassociates@yahoo.com

http://www.balaajirefractories.com/

For more information about our products and services, please visit our website or contact us directly. We look forward to partnering with you to achieve excellence in your refractory, insulation, and acid proofing needs.